Potting is the process of environmental protection by pouring a hardenable polymeric material into an electronic device, totally submersing and protecting the internal parts. Contact with us for information about potting and en-capsulation! Potting is one of the most popular applications for KPD automation Corporations multi-component dispensing equipment!

We offers an automatic [dosing machine for degassing, proportioning, mixing and high precision dosing of two component resins (epoxy, polyurethane, silicone..) in the atmospheric environment.

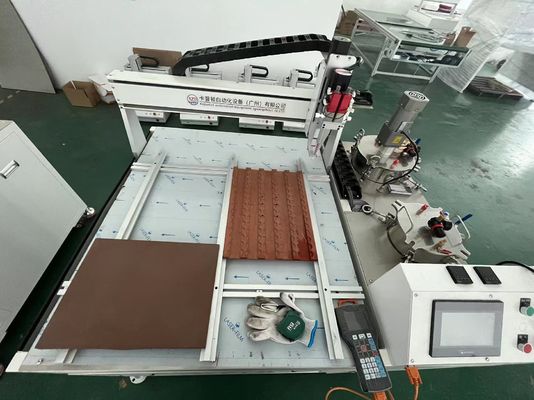

Machine Picture

Machine Working principle

Compound materials A & B are kept in two tanks separately. There are two sets of metering pumps inside the machine for metering A and B resin by setting ratio, draining out material individually from tank A & B. Liquid A & B mix with each other in the mixer pipe and dispensed out according to the programmable data.

Main features:

• Automatic loading of resin and hardener from barrels

• Servomotor controlled design ensures smooth acceleration has the ability to move precisely to prevent jerking

• High-low material qunatitiy level sensor in the tanks

• Automatic dosing feature allows the operator to take a break and return to operation again.

• Can be memorized 99 different loaded programme

• Dosing quantity and speed even smallest amounts can be precisely settable in the 7'' touch screen.

• Easy and fast programming capability with joystick

• After the operation, static mixer or dynamiccleaning equipment prevents the waste of static/dynamic mixer.

• Resin tank heater, Metering Pump heater, Resin Tube heater

Machine Prameter

| Models: | KPD-500 Automatic Multifunctional Glue Potting Machine |

| Suitable process: | It can be used as a stand-alone machine or with the customer’s original assembly line to achieve on-line gluing. |

| Proportion of glue: | 10:1 – 1:1 |

| hybrid approach: | Dynamic stirring mixing/static |

| Machine Stroke: | 500x500x100mm |

| speed | X,Y axle 400mm/s |

| accurate | ±0.05mm |

| Programme stock: | 999 |

| programmer | Teach-In Programming |

| metrological: | High precision metering pumps |

| control method: | PLC+touchscreens |

| input method: | Touch screen + buttons + IO |

| Appearance Material: | Industrial square tube welding + 6061 alloy + cold rolled plate |

| Drum size: | A barrel 30L, B barrel 10L (can be customised) |

| External Dimensions: | 1100×1350 X1600mm |

| Gum flow rate: | 1–80g/5sec (customised large glue volume available) |

| trajectory: | Punching points, walking straight lines, curves, drawing circles, arcs, squares, and other irregular shapes. |

| Supply Voltage: | AC220V/50HZ |

Options:

• Dispensing with Dozing nozzle or Static mixer/dynamic mixer

• Constant or Variable resin:hardener mixing-ratio

• Single or Multi Dispenser Potting

• Fixed or Moveable dosing nozzle (Dispensing)

(X-Y-Z axis movement or interpolation)

• Automatic Loading & Unloading of Trays

• Ability to dosing different quantities of raw materials to different locations in one program

• Automation: pre-heating and curing oven with conveyor

• Extra degassing tanks for uninterrupted production

Dosing Pumps

• Very precise even at very low volumes

• Constant mixing ratio ensures faultless dosing

• Metering pumps ensures minimal amounts of reactive mix

• Temperature controlled design

• Resistant to abrasion even when filled with high abrasive casting resins and does not require maintenance

Vacuum Tank Agitator

• Full homojenization

• No sedimentation

• Perfect degassing

Static Mixer /dynamic mixinng

• Perfect homogenization without dead space

• Abrasion resistant & low maintanence

• Temperature controlled design

• Ensures optimal viscosity of reactive compounds at constant temperature

• Provides very long service life with a closed cleaning system

Technical Specifications

Vacuum PumpUp to 1mbar

Nozzle Movement Motor: AC servomotor Linear X,Y,Z axis

Nozzle Movement DistancesX:700mm, Y:700mm, Z:100mm

Control SystemPLC

Power SupplyTriple Phase 220V +/-10%, 50 / 60Hz

Air Pressure6 Bar

Touch Screen7 inch

Barrel size: 10L,25L,40L for optional

Machine Application in Industry

Applications:

Potting&isolation &Casting: electronics componnets , PCB board, Capacitor, power supply, transformer, ignition coil, reverse sensor, circuit board, filter products ,underwater parts, electronic ballast ,aviation parts, aerospace parts....

Dispensing&Dosing : LED strip , led lamp , led bulb , aluminum,led screen , display module ,medical parts,medical liquid filling ....

Bonding&doming : LCD screen ,LOCA bonding,ABS plastic,different types of stickers , badge , keychains , souvenirs ,arts , photo frame , and other arts graphics.... Transformer , capacitance , power module , regulating plate ,protection module , generator , pressure package , soli relay ,fault indicator , Sensors , junction box , clutch , wave filter , water meter , boattery cover , rectifier and so on ..

Suitable Glue model

1K and 2-component polyurethanes, epoxies, acrylics, silicones, temperature, humidity and UV curing materials. Two component potting materials , 2-part compound materials, AB part compound materials , 2K silicones ,2K epoxies resin, Bi-component PU, Ployerster, Polyurethane, UV materials and so on

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!